The efforts to achieve building certifications with environmental sustainability criteria (such as LEED) require construction systems and materials that contribute to this effort to care for our environment. From its manufacturing process, its installation mechanism and thermal transmission reduction features, as well as the possibility of reuse, make the insulated panels system a more resource-efficient construction alternative. Let’s find out why.

LEED certification

In the field of construction, whether is housing structures such as apartment buildings, or those for productive use such as office buildings, factories or tourism facilities, the LEED* certification is highly valued and desired by owners.

LEED consists of a compendium of standards that must be met by a specific property that has been built, rebuilt, or refurbished, in order to obtain the endorsement and support that states that the building considerably respects the environment.

It is necessary for those involved in each construction project to decide if it will be oriented from its design to obtaining said certification since this implies considering a whole set of elements to articulate in order to comply with the requirements of the certifying authority.

Sandwich Panels Can Help

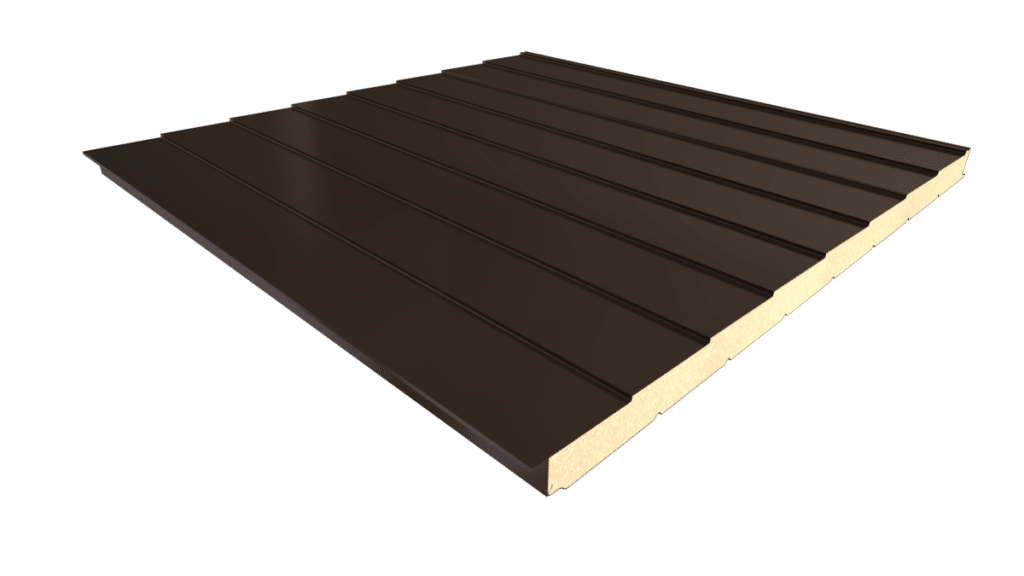

In this sense, the use of insulated panels for walls and roofs can be a solution that enables a building to obtain such certification. It is important to make clear that, as already mentioned, this will not depend only on a certain material that is used, but on the entire system with which the building has been erected, thus, the use of sandwich panels alone cannot guarantee that it will lead those interested to actually obtain the certification, just as no other material will be able to do it on its own. Nevertheless, sandwich panels can be considered as an alternative that adds to that set of elements that will make up the property and lead it to comply with the green requirements.

LEED Criteria

The LEED certification covers 6 criteria: sustainability, use of water, energy efficiency, resources and materials, internal environment and innovative design process. In this sense, the insulated panel is a candidate to fulfill at least three of these.

Sustainability

In regards to sustainability, which roughly means how reusable materials can be, sandwich panels are candidates for recycle. It is an uncommon practice, but it is definitely real and possible. Since this prefabricated product is partly assembled with tongue and grooves, if they are disassembled correctly and carefully, they can be used again for the covering of another structure if technical characteristics allow it (i.e. temperature, structure, etc.).

In the specific case of internal spaces, such as an office within a plant or a cold storage room, this reuse work can be easier since it is common to find that these facilities are made up of panels that are not attached to the main structure of the building, making them an even more versatile space. If desired, the panels could be disassembled and placed in another location to give it a new use, which means that it will not be necessary to demolish and destroy it and then rebuild it with new material such as the case of installations made of fixed materials (masonry blocks for example).

In line with the above, the panel production waste can be used at the factory, since the steel sheet can be recycled, while the polyurethane foam, either PIR or PUR, can be incinerated in order to obtain energy from combustion. Energy Consumption

Refering to energy, financial and operational efficiency is the effort and power required for the installation of the sandwich panels. The installation on the structure does not require a large amount of labor force or numerous on-site machinery, therefore the use of fuel is drastically reduced compared to construction systems based on materials such as cement, gravel and others for which large equipment, electro-mechanical and combustion machinery is necessary.

Also, during the life cycle of this product, on average they save up to 100 times the energy used to be produced. Additionally, given the thermal properties provided by the core foam (PUR , PIR or Rock Wool), they provide the building the ability to maintain an adequate internal temperature, resorting to a lesser extent to the use of heaters or air conditioners, which leads to a decrease in energy and fuel consumption.

Internal Environment

The aforementioned goes hand in hand with the criteria of the internal conditions achieved in the building, which will approach the optimal ones since the panels provide users of the property – call them workers, office workers, tourists, diners or residents – a pleasant environment without the use of cooling or heating resources. In addition, the insulating panels prevent the accumulation of moisture, thus preventing the proliferation of mold, fungi or bacteria.

To Conclude

As we can see, despite the first impression it may give to some, as it is a steel product, the insulated panels are an alternative to be considered when it comes to obtaining LEED certification, or simply for the construction of buildings that although do not seek to obtain the certificate, manager want an eco-friendly, efficient, time saving and also lasting alternative.

* Leadership in Energy and Environmental Design of the US Green Building Council