Self supporting panels

New ways of building, greater distance between support points or even elimination of supports, reduction and optimization of costs by using lighter metallic structures, faster installation and shorter execution time, are some of the advantages that we can learn about and benefit from in our future construction projects with insulating panels as a self-supporting system, leveraging its technical-constructive advantages.

Insulated Panels speed up building with quality

Technical building revolution, new materials, avant-garde construction systems… These are some of the advances achieved in our days for the execution of much faster, more efficient and “visually cleaner” works. Nowadays our society demands immediate products and services, with simple solutions and excellent results. And without forgetting that, if it has an attractive cost, so much the better.

When we think of carrying out a construction project, what comes to mind are slow construction processes, a large number of people, tools and equipment being mobilized to perform the tasks, different subcontractors involved in the various tasks and, therefore, complex coordination of time between different companies; and, at the end of all that process, a correct result, but perhaps not better than expected.

If what we are looking for is the reduction of construction processes, better finishes and a wide range of solutions at an unbeatable price, we should consider construction with insulated panels, which, due to their technical features, can even be considered a self-supporting construction system in some cases.

Less support points, less structural costs

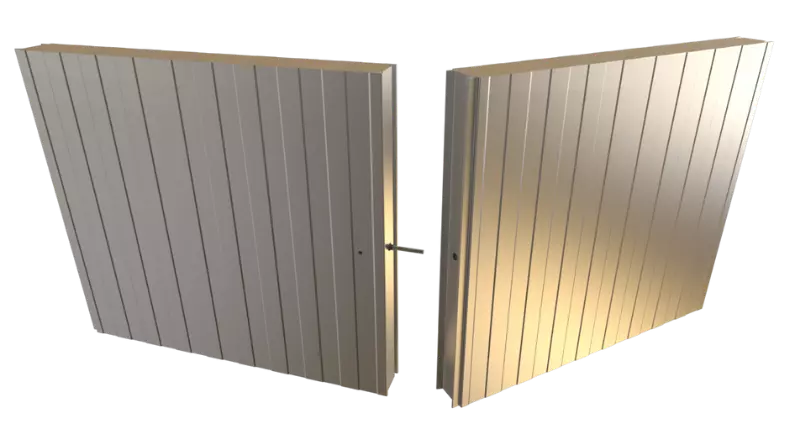

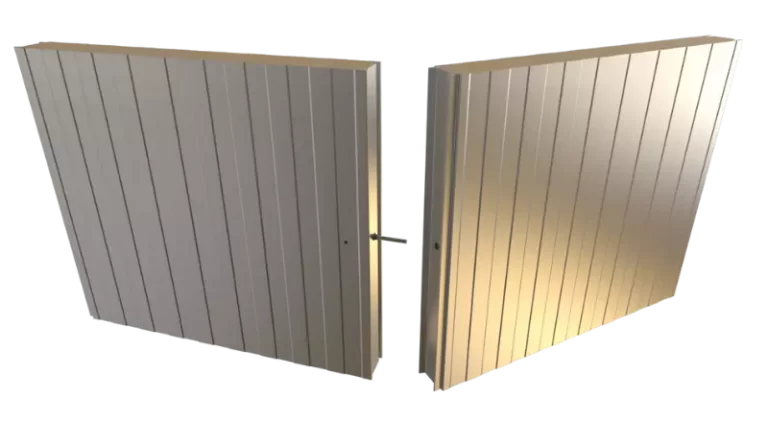

The construction with sandwich panels with outer steel sheets and polyurethane core, allows us to have self-supporting features, or what is the same, allows us to practically have more separate support points than usual. For those who are not used to the world of construction, this results in buildings with less supporting steel structure in sight, which translates into visually more attractive constructive pieces.

With this, we can achieve not only important aesthetic improvements, with cleaner and more open spaces, but also a substantial reduction of the load-bearing steel structure and, consequently, in many cases, a reduction of costs that benefit the final client. Today, steel prices are at historic highs (at the time of this article), and this means that a reduction in its use in the construction process can lead to substantial savings in the cost of the building.

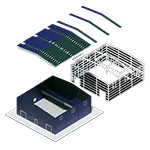

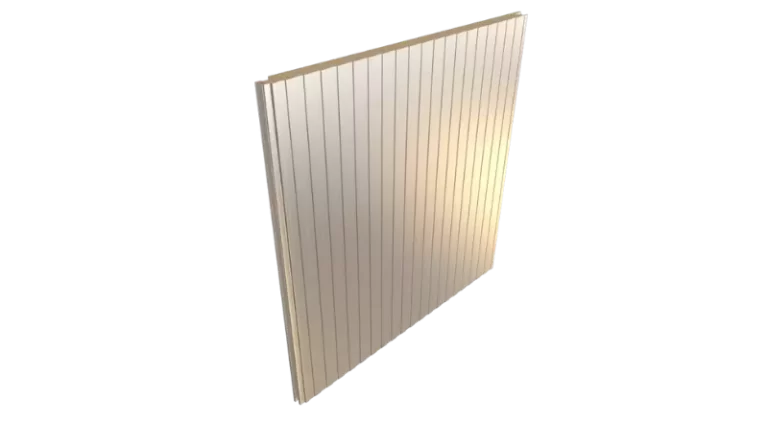

What is an insulated panel? It is a prefabricated product made of two outer sheets, which can be made of steel, aluminum, wood, among other less common materials. The most typical material used for its manufacture is steel. The core is made of a high-density material: polyurethane (PUR), polyisocyanurate (PIR) and rock wool. There are other compounds with which they are usually manufactured, but these three are the most recommended since they guarantee durability and safety due to their fire resistance.

Self-supporting insulated panels

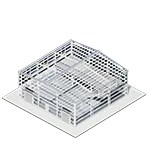

Self-supporting panels can be of two types: facade insulated panels and roofing insulated panels. We also see frequent applications of sandwich panels in cold rooms.

What does it depend on if the panel can be installed without any steel building structure? There are certain aspects that must be taken into account for this. It is essential that the assessment be carried out by qualified professionals with technical knowledge of the product.

The variables to be examined are as follows:

- Building dimensions

- Foundation conditions

- Wind or snow coefficients

- Seismicity of the area.

We must make it very clear that any panel installed in a self-supporting way in location “A”, does not mean that it will be self-supporting in location “B”. If any of the above conditions has a variation, no matter how small, its characteristics change and, therefore, its behavior will not be the same, so it is important to emphasize again, that a proper technical study determines with total security and guarantee its use.

Advantages of self-supported panels

The most common uses for this material are in industrial facilities, commercial buildings and in residential buildings as well. It can be used in roofs or covers, as well as in facades and the main advantages as a construction system are:

Ease of installation: due to its relatively low weight, and the fact that it is a system designed to be easily handled, installation does not require highly qualified labor. With a few hours of training and a basic tool kit it is possible to install the panels.

Short assembly times: Thanks to the long panel system, it is possible to cover large surface areas on facades and roofs in a very short time during assembly. The standard panel width covers nominally 1 m (3’3″), and usually allows maximum lengths of 11.90 m (39′)

Reduction of structural costs: Lighter structures have an impact on cost reduction. The increase in the price of steel in recent months has had a significant impact on the final price of the project. Therefore, the use of less steel in the structure benefits the reduction of the overall investment in construction projects

Durability and ease of maintenance: insulated panels have a high durability due to its outer structure in metal sheets and the composition of the high strength core. An appropriate selection of the coating, which responds to the environmental conditions of the construction site, guarantees good appearance and durability over the years.

The corrosion protection that these panels have starts with polystyrene coatings as a basic durable finish, up to HPS200 with very high resistance to salt corrosion in coastal areas or in aggressive gas industries. No specific or scheduled maintenance is required.

Greater insulation: by using greater thicknesses than usual, better thermal transmission performance is achieved between the interior and exterior of the building. The very low thermal transmission coefficient obtained with the properties of the panel core makes this material one of the best alternatives to reduce and maintain specific temperatures, with a finer thickness compared to other types of materials.

In addition to all these advantages are the direct and indirect environmental benefits of using less material in every way. The insulating panel is the result of cleaner and less polluting production processes and, in addition, less waste is generated during the construction work.

To conclude

We can say that the self-supporting insulating panels are a prefabricated system with multiple benefits as it is an industrialized product with many years of improvement, so it allows a quick and easy installation with very little labor and tools, it is aesthetically attractive and there is a wide range of colors and finishes.