Windows are more than frames and glass together

Construction of office and commercial buildings using insulated metal panels as cladding does not exclude large-format window openings. There are no limitations on shapes or dimensions. There are no limitations on shapes or dimensions. It is crucial to know the different types of window frames in order to make a more ad-hoc selection for each project.

Components of a window

To begin with, let us know how a window is formed: a glass or series of glasses, which is supported by a profile or window frame, as well as with a hardware system that defines the form of opening/closing in the most basic option, but as the industry has become more specialized, roller blinds can be incorporated, integrated to the whole window.

Components of a window:

- frames

- Glass

- Hardware

Comparable window characteristics

Windows have international classifications or standards, which allow us to compare different characteristics and properties of each manufacturer, according to our needs:

- Water tightness

- Air permeability

- Wind resistance

- Acoustic insulation

- Thermal transmittance

Windows Frames

Window frames can be made of different materials, the most common being

- PVC

- Aluminum

- Steel

- Wood

- Mixed

Depending on the material, they can provide different benefits in terms of durability, maintenance and energy efficiency.

When determining which type of window (glass and frame) to use, we must take into account: cost, thermal insulation, acoustic insulation, aesthetics, maintenance, safety, durability, ecological footprint and product disadvantages (condensation, corrosion or humidity).

Classification of window frames according to material

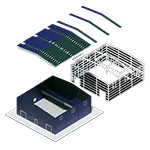

1. PVC frames: Polyvinyl Chloride (PVC) frames usually have good insulation properties, since it is not a conductive material. PVC frames or profiles have a series of hollows or air chambers separated by PVC walls, which have the function of housing steel elements that provide structural rigidity or in some cases fiberglass reinforcements are used, as well as water drainage or even improving thermal comfort.

The most common standard in the european market is a 3 in. thick profile with 5 chambers inside. It is important to mention that it is not because it has more chambers that it is more insulating, since the volume of air enclosed in them has a lot to do with what really improves the thermal insulation.

A few years ago it was said that PVC used to have fading problems with solar action. Manufacturers have improved their manufacturing formulas to achieve greater durability of the material in these conditions.

2. Aluminum Frames: One of the main advantages of aluminum frames is their durability. It is a material that stands the test of time very well. In addition, these profiles are manufactured from bauxite, a very abundant material in our environment, which allows us an extensive and accessible offer.

From the point of view of environmental impact, this material can be recycled up to 70%. They withstand severe conditions of wear and tear or marine corrosion. Due to their rigidity, they tend to have very slender cross-sections compared to those achievable with PVC frames, their main competitor.

It allows a wide variety of finishes: lacquered, anodized, two-tone, etc. To avoid condensation and improve thermal insulation, elements known as thermal breaks are usually installed. By placing a poorly conductive material such as polyamide (plastic) reinforced with fiberglass between the two sides that form the profile. Likewise, there are aluminum profiles that have an inner foam in some of their chambers, to improve thermal insulation.

3. Steel frames: At the beginning of the 20th century, within the rationalist architecture, as well as the impulse of industrial manufacturing, steel was used as a common material for the construction of window frames, increasingly thinner and more resistant. However, materials such as PVC or Aluminum with lower costs, replaced its massive use in large glass panels and increasingly thinner and “invisible” frames.

Part of this is because the strength of steel makes it possible to make structures 3 times thinner than an aluminum profile. The finishes can be galvanized, stainless steel or even corten. Steel systems may or may not have thermal bridging, depending on the location of the installation. They are usually high-end systems, with large glass spans.

4. Wooden frames: Wood has been used for many years as a superior material for the manufacture of windows. However, it has lost market share to new materials such as steel, aluminum and PVC. Wood as a material has great insulation properties. It is pleasant to the touch and we cannot deny its natural beauty.

The windows industry has innovated a considerable extent in the manufacture of this type of frames, including specific hardware for this material. They are usually used for environments where a touch of warmth or more rustic styles are required. The frames are usually made of solid wood or laminated wood.

The latter allow to improve the drying control in order to obtain an optimal dimensional behavior. They require maintenance, but there are a large number of products on the market that are suitable for their treatment. Some manufacturers offer the Forest Stewardship Council (FSC) certificate that guarantees that their raw material comes from forests that are cultivated with good practices and good management.

5. Mixed frames: The combination of materials allows taking advantage in some cases of the nobility of wood and its warmth characteristic in interiors, and using the exterior of the profile with an aluminum finish, which provides durability, modernity and distinction.

More detailed information on the types of glass, seals and hardware most commonly used in residential window installation can be found in the Glass and Hardware article.