Insulated steel panels are a thermal insulation material known for being an efficient construction solution that have been around for several decades, however, in recent years they have taken a greater popularity due in part to the concern of building more efficient structures in terms of cost, as well as in consumption of inputs and resources. In that sense, sandwich panels are definitely an alternative to achieve the desired efficiency that translates into profits for developers, builders, investors and users.

Insulated Steel Panels

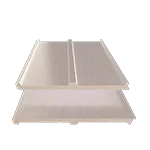

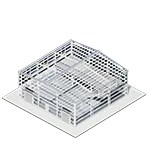

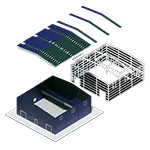

Insulated metal panels, as they are also called, are an insulation material that can be used for walls, for roofing and even for internal structures such as cold storage rooms. Panels are made of four main parts: the outer face, the foam core, the inner face and the tongue and groove joints with their ends. The two metal faces, that is, the parts that can be said to make up “the bread” of the sandwich, are plates or sheets usually made of steel, however, they are also found in other presentations such as wood, a material that in recent years has attracted attention because of contemporary architectural styles.

Panels Components

The two metal faces, i.e., the parts that can be said to make up the “bread” of the sandwich, are usually made of galvanized steel plates or sheets; however, they can also be found in other presentations, such as Corten steel or wood, which in recent years has attracted attention in contemporary architecture, especially for its decorative use in interiors.

The internal part of the panels is usually polyurethane, polyisocyanurate or rock wool, the first two being a non-organic raw material that adheres to the metal plates in a natural chemical process; while rockwool is a natural material that is processed at high temperatures to achieve foam formation.

There are expanded polystyrene or EPS panels on the market, which despite being less expensive, require evaluation and consideration of their reaction to combustion, flame, dripping and smoke in the presence of fire. For this reason, there are countries where their use is prohibited by law.

Finally, the joints and trims are very important, since they are the part of the panel in charge of joining each piece with its adjoining ones to form a uniform surface.

Insulated Steel Panels: Core types

Due to its composition, as already mentioned, insulated panels are composed of polyurethane (PUR) or polyisocyanurate (PIR). The primary difference between these two types of core is that PIR has better thermal resistance and transmittance properties.

The first property refers to the amount of heat that transits per unit of time and surface through the foam, something that is measured through the R-Value (and U-Value). This in simpler words refers to the insulating capacity that the material has with regarding heat. Thus, the lower the transmittance values (U value), the greater the capacity of the material – in this case the panel – to maintain the climate inside the property.

On the other hand, the R value measures the thermal resistance, which refers to the second property by which PIR panels are better than PUR, since the former have higher R values, which also means that in the event of a fire, the flame does not grow or spread quickly, and better yet, it burns itself out.

Rock wool core

Insulated steel panels with a rock or mineral wool core, as it is also called, have even greater insulating properties. These are usually used for the construction facilities for agribusiness, fish farming, pharmaceuticals or also tourism (hotels and restaurants) and supermarket industries. Thus, these panels are ideal to have warehouses for food, vegetables and fruits, medicines, salmon, tuna, seafood and other products and raw materials that need refrigeration or freezing. However, this type of buildings based on PIR or PUR panels is also feasible.

It is also important to mention that the insulated panels of PUR, PIR or Rock Wool provide acoustic advantages, since they have good insulation values against external noise. However, this will depend on the thickness, justl as in the case of their thermal properties. The most common thicknesses vary between 1 and 4 ¾ inches when installed as a ceiling, and from 1 ½ to 5 inches in the case of wall panel.

Insulated Steel Panels, a wise option

Definitely, insulated panels are to be more exploited by those involved in the design, architecture and construction industry, since although in some countries it is very widespread, there are others such as Latin Americans where not all companies consider sandwich panel in their building projects yet.

It is intriguing to see how large steel structure projects continue to be “mixed” with traditional cladding materials such as brick or block, even though this entails significant disadvantages in terms of time savings, money savings, environmental issues and, in general, construction efficiency.

The reasons for this can vary: from lack of knowledge on how to choose the product to its availability on the, or even cultural factors that are deeply rooted in the contractors and other.

Despite this, insulated steel panels are having increasing growth in use due to the fact that the protagonists of the construction sector are realizing the benefits, advantages and applications that this thermal insulation material has in terms of efficiency, ease of installation, low impact on environment, time to market and many more. That is why a good number of residential, hospitals, entertainment, office facilities and many other types projects are being projected and erected with panel sandwich as cover. In another blog post we will write about the constructive, financial, efficiency and ecological advantages of the insulated panels.