PROTECTIVE STEEL COATINGS FOR INSULATED METAL PANELS

Polyester, PVDF, Granite® HDX, PRISMA, or HPS200 Ultra® are some of the types of steel coatings that can be applied to protect and give the final finish to the exposed steel sheet on insulated panels.

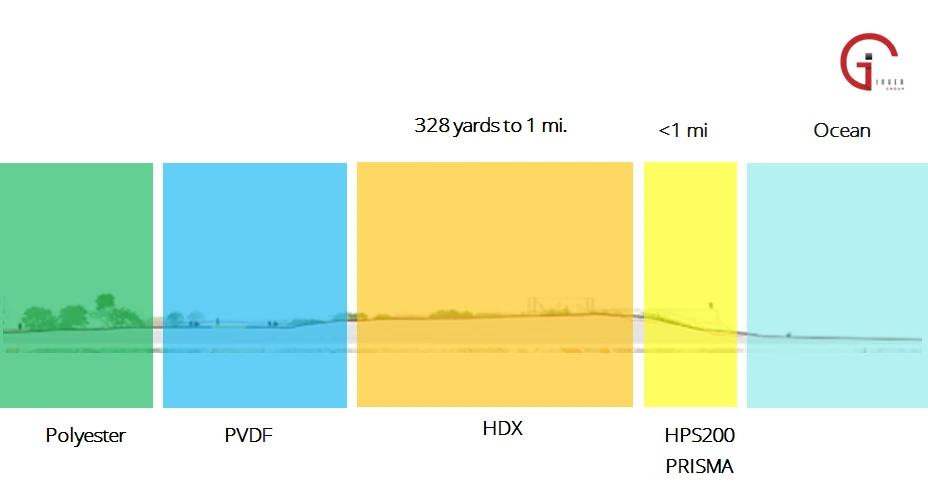

The choice will depend on the location, use, and exposure of the panels to corrosive environmental agents. Most of these coatings are applied in industrialized processes at the time of manufacturing the steel coil. This coil is then used to fabricate sandwich panels.

In this article, we will learn about the most notable properties and characteristics of these types of finishes. In this way, we will be able to get an idea of the possibilities and applications for the construction of buildings using sandwich panels.

Why is it important to know about steel coatings?

Choosing an appropriate steel coating for insulated panels used in our projects is important to ensure durability.

With this article, you are going to understand and know the difference between some of the most common steel coatings used in the manufacture of the sandwich panels.

This is very important to know because the location of the construction project with respect to its exposure to natural environmental corrosive agents, mainly related to the proximity of coastal regions, will determine which steel cladding is best for the insulated panels used. In addition, there are possible effects of exposure to abrasive environments that can affect the performance of insulated metal panels, as can occur in some factories.

Polyester Steel Coating

Polyester paint is the most common paint used in the manufacture of insulated metal panels. They contain hardened polyester resins, which provide high weather resistance and very good gloss preservation. At the same time, it maintains color and finish stability for many years.

It has a high resistance to ultraviolet rays and strong temperature changes. In contrast to these benefits, polyester paint tends to crack if there is a high functional load, as in the case of impacts and bends in the material. It also presents a lower resistance to oxidation and chemical agents than other coatings we are going to mention.

In short, we are talking about a good coating, but with a basic level of performance.

PVDF (ArcelorMittal)

ArcelorMittal‘s PVDF is a factory-applied paint with a primer base. The combination improves the properties of the surface to which it is applied.

In addition to having greater resistance to ultraviolet radiation and sunlight, it is ideal when there are deformations or bends in the material. At the same time, it presents better resistance to corrosion than polyester paint. It is a smooth finish with a long life when exposed to the exterior.

PVDF has excellent chemical and weather performance, along with considerable resistance to distortion and creep at low and high temperatures.

Although the chemical resistance is good, the polymer that makes it up can be affected by very polar solvents, primary amines, and concentrated acids.

The PVDF material has, like all halogen compounds, a self-extinguishing behavior without the need for the addition of specific additives. In the case of fire, it releases smoke to a very limited extent.

With a coating of only 35 microns, it has very high corrosion and UV resistance values.

Granite® HDX (ArcelorMittal)

HDX is a product also manufactured and patented by ArcelorMittal, which offers an ideal coating for external applications. It is a steel coating with higher corrosion and UV performance than PVDF. This type of application has a minimum coating of 55 microns.

It offers a granular surface that provides high surface hardness and resistance in handling and forming processes.

It is ideal for building projects located between 328 yards and 1 mile away from the coastline (exposed to salt corrosion).

Prisma Steel Coating (Tata Steel)

Prisma is a product of Tata Steel, which uses a Galvalloy type metallic coating, also from the same manufacturer. It is fabricated with a special mixture of 95% zinc and 5% aluminum. This system ensures a higher barrier of protection against highly corrosive environments.

Prisma has a new and modern range of colors, including plain, metallic, or very natural matte colors. Due to its wide range of colors, it is ideal for facade applications.

Due to its chemical composition, like the previous coatings, it does not need additional components to present an excellent behavior against external fire. Panels coated with Prisma are guaranteed for 30 years.

HPS200 ULTRA (Tata Steel)

Tata Steel’s HPS200 Ultra coating is a coating designed to perform in some of the most demanding environments. In places with high environmental corrosion.

It is a coating with a nominal thickness of 200 microns. With this, we find a finish with a durability far superior to those previously mentioned. Offering sustainable solutions for the coating of buildings where longevity and durability are essential.

HPS200 Ultra can be combined with Scintilla (also patented by the same manufacturer). This has a nominal depth of 50 microns, which makes dust accumulation unlikely, providing an “embossed” effect from the factory.

In Summary

For protective paint finishes for metallic sandwich panels, we have the following:

From a basic polyester paint finish, going up in UV protection, handling, and scratch resistance performance with PVDF. Going through HDX for environments exposed between 328 yards and 1 mile away from the sea.

On the other hand, the Prisma finish offers a very wide range of colors with high performance against ultraviolet rays and corrosive environments, up to the top of the range: the HPS200 Ultra, which is prepared for the most extreme environmental conditions.

Knowing the properties of each of these coatings and choosing the type of paint that best suits the conditions of our building project, will allow us to extend the life of the insulating panel used either as a roof or facade.