PIR boards for cold room floor insulation

PIR foam boards are a construction element that has many applications, but in this article, we focus on their use in the insulation of the floor of cold rooms. We will know some details of its manufacturing process, its presentations, as well as the most common sizes.

We explain basic concepts such as positive and negative working temperatures in cold rooms and what to consider when designing cold rooms with insulating materials.

This is a very brief explanation of how we must carry out its assembly, as well as some aspects that we must take into account before carrying out the work.

Insulated panels cold room

A cold room is an enclosed space with a controlled temperature. Its main uses are usually in the food, pharmaceutical, flower trade, and other industries.

If you want to know more details about the cold rooms made with insulating panels, you can read our article Using Insulated Cold Storage Panels for Cold Rooms where we expand all the general information about them, their uses and considerations.

Cold Rooms and Freezer Rooms

Before delving into the use of PIR foam boards as the base of the floor in refrigeration rooms, we will know some basic concepts about the working temperature, which are positive or negative temperature according to Celsius scale.

Why is it important to know these concepts, because knowing the temperature conditions at which the cold room must work, we will have an accurate assessment of whether it is necessary or not to use rigid PIR foam boards on the floor. So, let’s look at this in a little more detail.

These values are widely used in the food industry and, therefore, many of the criteria are based on the usual processes in this sector. This makes it common to hear references based on the part of the process within this industry that we are going to value. For example: Depending on the food we want to preserve, the ideal temperature of the cold rooms will vary; for this reason, we can find positive (cold rooms) or negative (freezer rooms) temperatures.

Positive temperature: cold rooms

The cold rooms that are usually used in the handling of products such as fruits, vegetables, or sausages, usually work in positive temperatures. In this case, the ideal working temperature is between 0º and 10º degrees Celsius (32 to 50 F). This temperature ensures the good preservation of these products.

It is a system used to preserve food in a fresh state without affecting the conditions of the food.

Negative temperature: freezer rooms

When refrigeration or even freezing of products is necessary to extend the shelf life of handled foods, we are already talking about working temperatures between 0º to -28º degrees Celsius (32 to -18 F). We can obviously deduce that the word negative refers to temperatures below 0 on the centigrade scale.

These temperatures make it possible to keep perishable products, produce, and food in a frozen state.

PIR foam

PIR (polyisocyanurate) foam is widely used as rigid thermal insulation. It is a thermosetting polymer, which means that it undergoes an irreversible hardening process upon curing from a viscous liquid. This curing process is carried out by heat and can be promoted by applying high pressure or by adding a catalyst to the mixture.

The initial raw materials are very similar to those used in the manufacture of PUR foams, except for the amount of methylene diphenyl diisocyanate (MDI), which has a much higher concentration, and the amount of polyester polyol. The result is a complex polymeric structure.

That said, we can say that there is a diversity of PIR material but, depending on their chemical composition, they can result in application products according to your needs. Higher stiffness, better chemical stability or, depending on the case, superior thermal resistance can be sought. All with equivalent densities, which facilitates handling.

Use of rigid PIR boards on cold room floors.

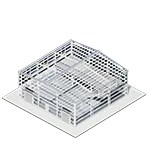

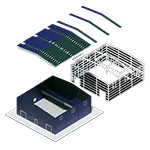

The efficiency of the use of PIR foam boards and PIR panels for the installation of cold rooms is usually oriented to be used in the construction of rooms with negative temperatures. The effectiveness of the insulation in the enclosure of the cold room is a function of the reduction of gaps or cracks from the cold room to the outside. This is why it is important to use PIR foam boards in the floor of the room.

The use of PIR rigid foam insulated panels on walls and ceilings, as well as PIR rigid foam sheets, provides a very efficient and complete system, which guarantees the best conservation of working temperatures inside the cold room.

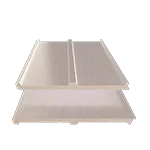

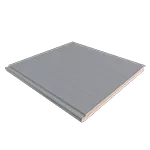

PIR foam boards are usually coated on both sides with a Kraft type paper that protects them during handling on site. The most common dimensions are 1200 x 2500 mm (47 x 59 inches), to facilitate handling and installation. In terms of thickness, we find dimensions of 50, 60, 80, 100, 120 and 150 mm. (2, 2-½ , 3, 4, 4-¾ and 6 inches).

The main characteristics that we can highlight are:

1) It is a material with high resistance when subjected to compression forces.

2) It is easy to handle and adjust on site.

3) It has great rigidity and low weight.

The correct way to install the PIR panel sheets is:

1) Prepare the supporting surface. Under the whole area where the cold room that will work with negative temperature will be built, a firm support surface must be ensured.

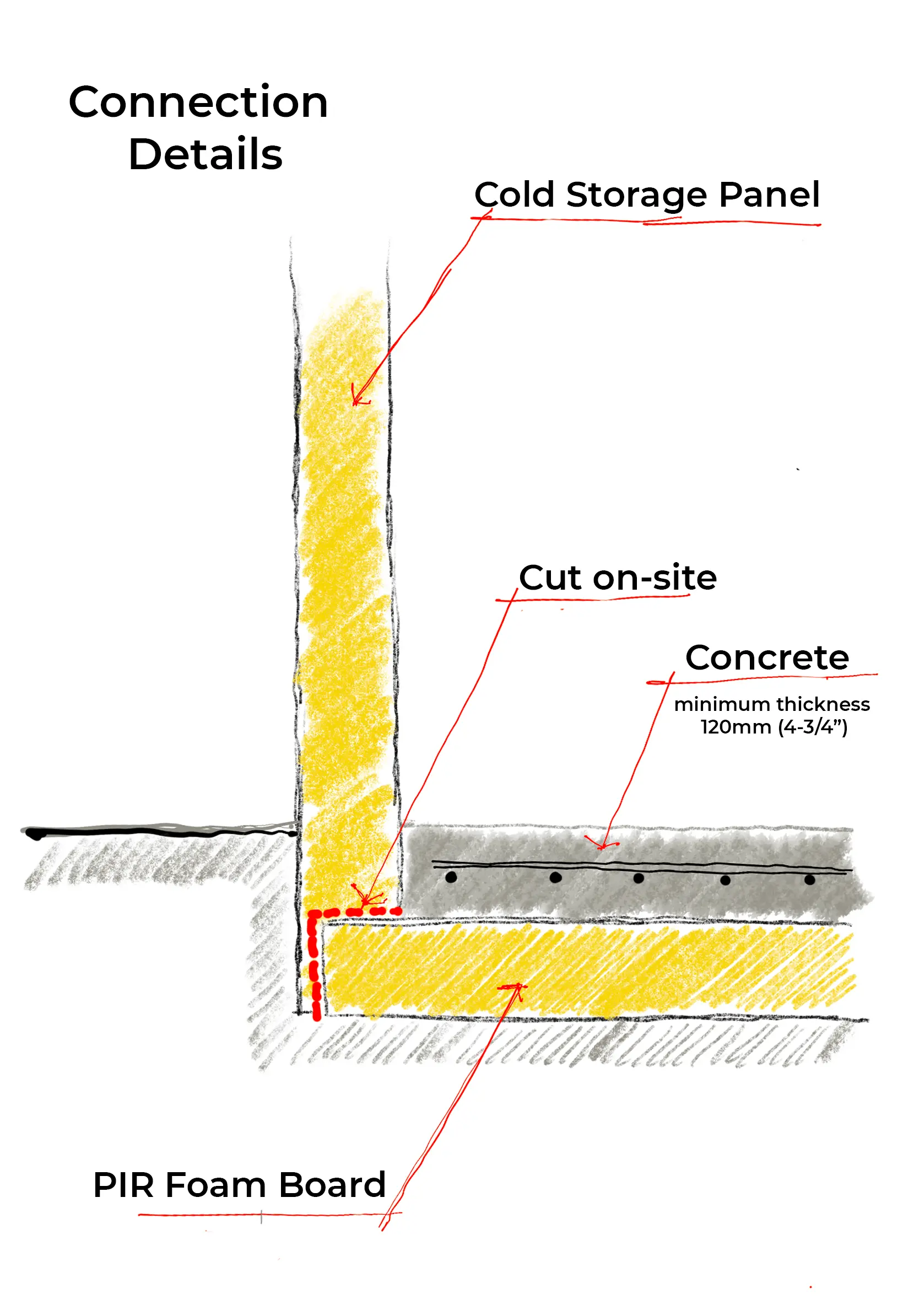

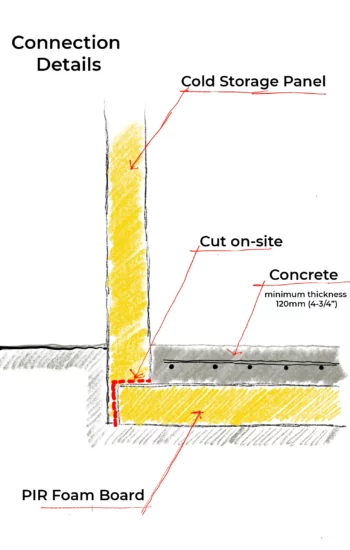

2) Install the PIR boards, fitting perfectly and connecting with each of the boards, but at the same time with the vertical panels of the cold room. This ensures the integrity of the cold room.

3) Place a layer of reinforced concrete to protect these plates from the circulation work inside the cold rooms.

The recommended thickness for such a reinforced concrete slab is usually between 12 and 15 cm (4-¾ and 6 inches). It is recommended that a specialized technician determine the thickness and resistance of the concrete, according to the particular conditions of the floor and the workload inside the cold storage room.

4) In some cases, it is necessary to place a vapor barrier between the panel and the reinforced concrete or from the floor to the PIR board.

The vapor barrier is a protective film that prevents the transmission of moisture. Consult with a local specialist technician to determine the need for its use.

These steps are indicative and illustrate a standard and generalist process. Each project should be analyzed and designed by a technical team specialized in this type of camera, which should study the particular conditions of the project

To Conclude

When working in cold rooms at negative temperatures, we must ensure the maximum possible hermeticity in all the components that make up the cold room, from the walls, roof, access doors, and even the floor of the cold room. This is where the use of PIR foam boards becomes so important.

The PIR foam boards are the supporting base for the insulated cold storage panel walls. We must ensure their continuity in the PIR foam, and this is achieved by cutting the panels on site. A small reinforced concrete slab is placed on top of the PIR foam panels to facilitate circulation inside the cold room.

Industrial cold rooms working at negative temperatures made with insulated panels and PIR foam sheets are the best option and guarantee for those industries that require the maintenance of controlled temperatures with a low electrical consumption of the refrigeration equipment.