Rockwool insulated panels are perhaps the best choice for fire protection of an industrial building and is an efficient acoustic barrier for your project.

Rock wool panels are specifically designed to provide maximum protection in case of fire.

The use of rock wool as core foam allows you to use these panels as acoustic barriers with a wide range of uses. From sound protection barriers for roads to machine rooms in factories, these panels are a great option when regulations are to be met.

Then, are these the one option to select for warehouse? There is not a simple answer, and this post might help you decide.

A special type of panel

Like its smaller siblings –panels with PUR and PIR cores– rock insulated metal panels, just as these, are made of two layers of external metal sheets, either galvanized steel or aluminum. As such, it allows similarity of finishes in its exterior sheets and its morphology is very similar to that of other panels. The difference is that its core is made of mineral wool. While PUR and PIR panels are manufactured with average densities of 2.5 lb / ft3; those made of rock wool can be manufactured with densities from 6.2 lb / ft3 to 8.7 lb / ft3. Therefore, greater benefits and durability are achieved with this panel.

Taking the above as an introduction, let’s learn a little more about this product and its advantages, so that we can have a better criterion to choose the panel that best suits the requirements and budget of our project.

Rock wool core

Rock wool or mineral wool is a material that is manufactured using a natural rock such as basalt as raw material, as well as other compounds to a lesser extent. Basalt is a very common and abundant type of volcanic rock on our planet.

Its manufacture involves heating the volcanic rock in furnaces to a temperature of 2912 degrees Fahrenheit, where it liquefies and converts into some sort of magma, which is processed to obtain long fiber-like strands that vary according to their uses. It has a useful life comparable to a building of up to 50 years.

Uses of Rock Wool Panels

The rock wool sandwich panel can be used both in outdoor areas such as facades or roofs for commercial or residential buildings. But it is also common to use it to separate interior walls that need to have maximum fire resistance or spaces that need the highest acoustic insulation properties.

Therefore, we can highlight two major areas of use for this type of sandwich panel:

- Spaces that are sensitive to fire protection and retardation, both on facades, roofs and interior partitions. These can include homes, large crowd sites, public areas, industrial buildings, etc.

- Buildings where acoustic insulation is needed: Spaces where sound insulation or absorption is important for the project. This can be shopping centers, work areas with high noise emission, public areas, residential zones, etc.

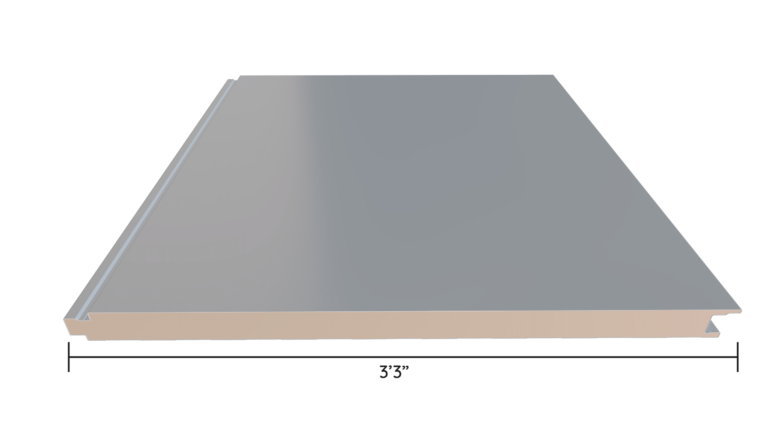

Dimensions of the insulating rock wool panel

The rock wool panels have a manufacturing width of 3’3” and length (limited by transport) of up to 39’. Its thickness can be of 2”, 3”, 4” and 4 23/32”.

Main properties and advantages

Fire protection

The mineral fibers of the core allow to obtain a Euro fire test classification of type A, S1, d0. This is the highest and safest ranking possible in terms of fire safety regulations. Our panels can be manufactured from 2” to 4 23/32” thick, where it is possible to meet fire resistance times of up to Ei180 minutes. And in special cases, it can be manufactured for an Ei240 minutes.

Fire resistance

|

Thickness (in.) |

Ei (minutes)* |

|

2” | 30 |

| 3” |

120 |

|

4” |

180 |

| 4 23/32” |

180 |

* time elapsed while panel preserves its stability, integrity and thermal insulation

Thermal insulation

The structure of the rock wool core allows it to have small air spaces that reduce the capacity of the material to transmit heat or cold by conduction.

Sound proof

The qualities of the rock wool core have sound absorbing properties, providing noise reductions, according to the thicknesses used.

Durability

Being an inorganic material, it performs very well over time, it does not deform or deteriorate. As well it reduces the formation of mold.

Is rock wool the best option for insulated panel?

In conclusion, we can assert that, due to their density as well as physical and chemical properties, insulated rock wool panels are one of the materials that provide the best resistance to heat and delay time in the spread of fire, thus becoming a premium alternative for certain types of projects that require maximum security, as well as superior sound insulation benefits.

It is difficult to establish whether mineral wool material is the best alternative for all projects or to conclude whether it is better or worse than using PIR or PUR panels. This is so because the decision on how to choose insulated panels correctly will always depend to a great extent on different factors such as the type of project, the use of the building, the available budget, the applicable local regulation and the benefits to be obtained from this material.